Industry News

Flat Wire Motors And Hair-Pin Motors Technology

The classification of flat wire motors and the process of Hair-pin hairpin motors.

With the continuous development of the new energy vehicle industry, the production and sales of electric vehicles have exploded, and the demand for high-performance and high-efficiency motors is also increasing. The high efficiency, light weight, miniaturization and low cost of the electric drive system are the future trends; and the integration of the electric drive system and the flat line of the motor are the main technical routes to achieve light weight and miniaturization. Compared with round wire windings, flat wire windings have achieved rapid development due to their unique advantages, and are widely used at home and abroad, becoming a hot direction in the research and development of new energy vehicle motors. Among them, the manufacturing process of Hair-pin (hairpin) flat wire motor has become the first choice of major electric vehicle manufacturers. The following introduces the classification of flat wire motors and the process of Hair-pin motors.

Classification of flat wire motors

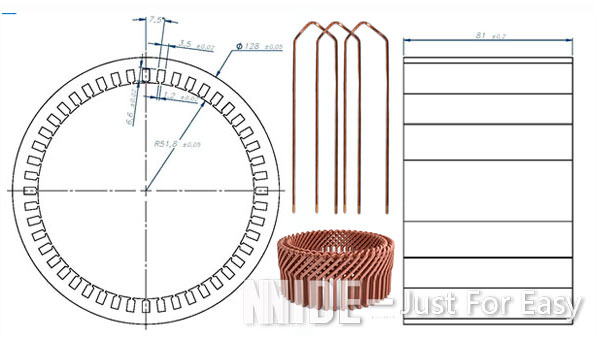

Flat wire motors can be divided into concentrated winding flat wire motors, wave winding flat wire motors and Hairpin flat wire motors according to product types, among which hairpin flat wire motor technology is the mainstream technology that is widely used.

The concentrated winding is made of flat copper wire to form a single-tooth winding, and one tooth corresponds to a single-tooth winding installation, because the short-span coil end can effectively reduce the end size, and its process is simpler than the Hairpin flat wire motor . Due to the excessive fractional harmonics, this structure has the disadvantages of large torque ripple and complex radial force; in order to reduce the cogging torque and torque pulse vibration, the structure needs to ensure roundness and simultaneous The axial degree and the uniform distribution between the teeth have higher assembly requirements. Concentrated winding technology is widely used in the field of industrial motors, and some manufacturers in the field of new energy vehicle motors are also researching and applying it. For example, some hybrid models currently adopt this technology, and have achieved good results with its unique fractional slot concentrated winding, split stator structure and related optimization technologies.

The flat wire motor with wave winding adopts the continuous winding of the winding to be integrally formed and then inserted, or inserted into the stator slot while winding to form a wave-shaped end. Compared with the Hairpin flat wire motor, it has no solder joints, which can further shorten the height of the winding end and reduce the motor size. However, the slot size of this type of stator assembly is wider, which makes the cogging torque larger, the torque ripple is higher, and the NVH performance is poor, so it needs to cooperate with the electromagnetic

Multi-objective optimization design and other measures to improve optimization; at the same time, its production cost is higher than that of Hair-pin motors.

Hair-pin (U-pin) motor is also known as hairpin winding because its winding resembles a "hairpin". One end of the enamelled flat copper wire is preformed into a U shape, and then inserted into the stator core slot, and the other end is twisted and processed into a frog leg. shape, and then welded together to form a wave-shaped winding. Another I-PIN winding process directly inserts the straight copper wire into the stator core slot, and then twists both ends into a frog leg shape and welds them together to form a wave winding, which saves the pre-forming process in the U-PIN winding . Both U-PIN and I-PIN flat wire windings belong to the second generation of axial embedded windings. Compared with the two, they are comparable in the highest efficiency and peak torque, but the latter has a higher slot fill rate than the former. Continuous torque and continuous power; due to the latter having twice as many solder joints, the winding end size is slightly increased, and the risk of solder joint failure is also higher. Hair-pin winding process is a process route widely used at home and abroad.

Hair-pin coil process

Card-issuing technology is a large-scale, high-quality, low-cycle stator production technology. The process chain mainly consists of the following five steps:

1. Forming (straighter enamelled copper flat wire, stripping, cutting, bending),

2. Insertion (combined insertion of stator slot liner and hairpin coil),

3. Turn your head

4. Welding

5. Insulation

In addition to the insulating paint film insulation between the copper wires of the hairpin winding, the stator slot liner is added to separate the conductors from each other, so as to eliminate the direct contact between the turns or the conductor and the stator core, improve the insulation performance, and enhance the short circuit protection. Therefore, it is necessary to insert insulating slot paper. The common slot paper shapes are O-type, C-type, B-type, S-type, etc., as shown in Figure 5. The B-type slot liner eliminates the corner gap of the S-type slot liner and enhances the protection against short-circuit faults.

In the paper insertion process, the insulating slot paper is inserted into the stator slot in advance. As the number of flat wire layers increases, the difficulty of the process also increases significantly. The PIN forming process includes stamping forming, spring machine and CNC CNC equipment automatic forming, etc. The former has fast forming speed and low cost but causes greater damage to copper wires, while the latter has good versatility and causes less damage to copper wires but has higher equipment costs.

After the PIN is formed, it is pre-inserted into the profiling tooling. As the number of flat wire layers increases, the difficulty of automatic insertion of the cross-conductor also increases. Then insert all the PINs in the profiling tooling into the corresponding design dimensions in the iron core as a whole. This process requires high precision of the equipment.

Then through the flaring, twisting and flattening process, the end of the winding is flattened for welding. At present, TIG welding and laser welding are the most popular for flat wire motors, and other companies are also experimenting with welding methods such as CMT cold welding.

After the welding is completed, it is necessary to conduct electrical performance testing of the winding, phase resistance, phase inductance and its balance testing, and voltage and resistance testing, etc., and then apply the coating after passing the testing test. The coating process is divided into powder coating and liquid coating according to the different coating materials. The process sequence of the two is different. According to different materials, the dipping process includes traditional dipping, vacuum dipping, vacuum pressure dipping, drip dipping, EUV dipping, etc.

NIDE focuses on motor manufacturing solutions, including BLDC brushless motors, induction motors, universal motors, hairpin motors, which are mainly used in household appliances, industrial motors, automotive motors, new energy motors, aerospace motors and other fields. We can provide customers with local services, remote services, and overseas services.