Industry News

Automobile motor manufacturing-Flat wire motor manufacturing

The current new energy vehicle motor mainly adopts flat wire motor manufacturing technology.

With the increasingly prominent global energy and environmental issues, the development of new energy motors has become an important trend in automobiles and other fields. The following are the development trends of several new energy motors:

Electrification trend: The popularity of electric vehicles has promoted the rapid development of motor technology. As the core component of electric vehicles, the efficiency and performance of electric motors have become important factors for consumers to choose vehicles. Therefore, electric vehicles will be one of the main application fields of new energy motors in the future.

High efficiency and energy saving: The development of new energy motors not only needs to improve their efficiency, but also needs to reduce costs. To this end, some new technologies are widely used, such as ironless motors, permanent magnet synchronous motors, AC asynchronous motors, etc. These technologies can increase the efficiency and power density of the motor, and can reduce the size and weight of the motor.

Integrated development: With the integrated development of motors and control systems, motors can better meet the needs of automobiles and other fields. For example, the motor and battery are integrated, which can improve the charging efficiency and service life of the battery. In addition, integrated technology can also reduce overall system cost and improve system reliability.

Intelligent application: With the popularization of smart cars, new energy motors also need more intelligent applications. For example, electric motors can be integrated with vehicle control systems and navigation systems for autonomous driving and route planning. In addition, intelligent technology can also improve the operating efficiency and safety of the motor.

The current new energy vehicle motor mainly adopts flat wire motor manufacturing technology.

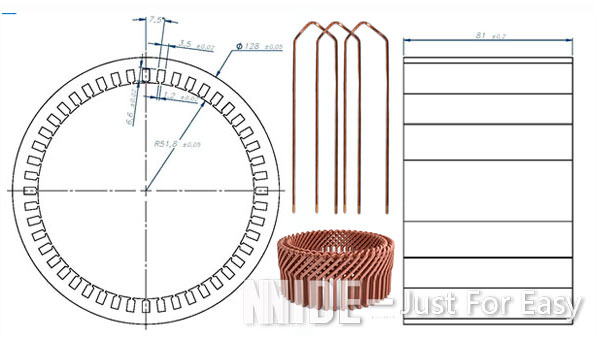

How flat wire motors are manufactured

Flat wire motors, also known as pancake motors, are manufactured using a variety of techniques depending on the specific design and application requirements. However, the general steps involved in the manufacturing process include:

Coil Winding: The first step involves winding the flat wire around a mandrel or core to create the stator coils. This process can be performed manually or using automated machines, depending on the required precision and volume.

Stator Assembly: The stator coils are then assembled into the stator core, which may be made of laminated steel or other materials depending on the application.

Magnet Assembly: The permanent magnets are assembled into the rotor core, which may also be made of laminated steel or other materials.

Rotor Assembly: The rotor core is then assembled with the bearings and other components, such as the shaft and end caps.

Motor Testing: Once the motor is assembled, it undergoes various tests to ensure that it meets the performance specifications and quality standards. These tests include electrical and mechanical testing, as well as environmental testing to simulate different operating conditions.

Overall, the manufacturing process for flat wire motors requires a high level of precision and expertise to ensure that the motor performs reliably and efficiently.

Automobile motor manufacturing includes the following steps:

Casting: The engine block, cylinder head, and other components are cast in a foundry using a mold made of sand, clay, or metal.

Machining: The cast components are then machined to achieve the desired shape and size, and to ensure that they meet the required specifications.

Assembly: The various components of the engine, such as the crankshaft, pistons, and connecting rods, are assembled together using specialized tools and equipment.

Testing: The completed engine is then tested to ensure that it meets the required performance standards and emissions regulations.

The process of manufacturing an automobile motor requires precision and expertise, and is typically carried out by specialized manufacturers who supply engines to automobile companies. With the rise of electric vehicles, the manufacturing process is shifting towards the production of electric motors and batteries.